Epoxy table has taken the world of interior design by storm, becoming a centerpiece in modern homes and offices. Their unique blend of natural wood and vibrant resin creates a stunning visual that is both art and furniture. This growing popularity comes from the incredible versatility of epoxy resin, which has revolutionized custom furniture making by allowing for designs that were once impossible. Whether you’re drawn to a striking “river” table or a piece with intricate artistic details, epoxy furniture offers a way to bring a truly one-of-a-kind statement piece into your space.

This guide will walk you through everything you need to know about these captivating creations. We’ll explore what they are, the different styles available, and how they’re made. You’ll also learn about maintenance, cost, and how to choose the perfect epoxy table for your decor.

What is an Epoxy Table?

An epoxy table is a piece of furniture, typically a table, created by combining wood with epoxy resin. The key component is the epoxy resin itself—a two-part system consisting of a resin and a hardener. When mixed, these components undergo a chemical reaction that causes them to cure into a hard, durable, plastic-like surface. This process allows creators to fill natural voids in wood, join separate pieces of wood, or encase objects to create a smooth, glossy tabletop. The result is a highly durable and visually stunning piece of custom furniture.

Types of Epoxy Tables

The beauty of epoxy lies in its adaptability, leading to a wide range of designs.

River Tables

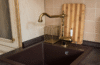

This is perhaps the most iconic style. A river epoxy table features two pieces of live-edge wood with a stream of colored epoxy resin flowing between them, mimicking a river cutting through a landscape. The natural, uneven edges of the wood create the “riverbanks,” making each table a unique geographical map.

Live Edge Tables

Live edge resin tables preserve the natural, un-sanded edge of the wood slab. Epoxy is often used to fill cracks, knots, and voids in the wood, stabilizing the slab while highlighting its organic imperfections. This style celebrates the raw, untamed beauty of the wood itself.

Wood and Epoxy Combinations

These designs go beyond the river concept, using epoxy to create bold patterns or fill large sections of the table. A popular wood and epoxy combination involves using “cookies” or cross-sections of logs, with epoxy filling the gaps between them to form a solid, mosaic-like surface.

Artistic Epoxy Tables

For the truly adventurous, artistic epoxy tables are a canvas for creativity. Artists can embed objects like stones, shells, flowers, or even LED lights within the resin. They can also use complex pouring techniques to create swirls, waves, and abstract patterns, turning a simple table into a functional work of art.

Other Designs

Epoxy also fits well into other design aesthetics. Minimalist tables might use a single, solid color of epoxy with a clean-lined piece of wood, while industrial designs could pair a thick epoxy top with a rugged metal base.

The Epoxy Table Making Process

Creating a DIY epoxy table is a rewarding but meticulous project. Here’s a simplified step-by-step guide.

First, you must choose your wood. Hardwoods like walnut, maple, and oak are popular choices due to their durability and beautiful grain. The wood must be completely dry, with a moisture content below 12%, to prevent issues during curing.

Next is preparing the wood. This involves flattening the slabs, sanding the surfaces, and building a sealed mold around them to contain the liquid resin. Any cracks or holes on the bottom of the wood should be sealed to prevent leaks.

After that comes mixing and pouring the epoxy resin. Following the manufacturer’s instructions is critical. The resin and hardener must be mixed in the precise ratio, usually for several minutes, until fully incorporated. Pigments or dyes are added at this stage. The epoxy is then poured into the mold. For deep pours, this may need to be done in layers to manage heat buildup.

The curing process can take anywhere from 24 to 72 hours for the resin to harden. The temperature of the room plays a significant role in curing time. Once cured, the table is de-molded.

Finally, the finishing touches. This is the most labor-intensive part, involving sanding the surface through progressively finer grits to achieve a smooth finish, followed by applying a topcoat of oil or ceramic coating to protect the surface and give it a desired sheen.

Best Epoxy for Tables

Choosing the right epoxy is crucial for a successful project.

The best epoxy resin for tables is typically a deep-pour or casting resin. These are formulated to be poured in thick layers (up to 2 inches or more) without overheating and cracking. They also have a lower viscosity, which helps release air bubbles.

For a crystal-clear finish, look for a high-quality, UV-resistant epoxy. Cheaper resins can yellow over time, especially when exposed to sunlight. If you plan to use the table outdoors, UV resistance is non-negotiable.

Self-leveling resin is designed to spread out evenly, creating a smooth, glass-like surface with minimal effort. This is ideal for flood coats or sealing the top layer of a table.

When it comes to brands, products from companies like EcoPoxy, MAS Epoxies, and TotalBoat are highly regarded by professionals for their clarity, durability, and user-friendly properties.

Epoxy Table Maintenance and Care

Proper epoxy table care ensures your investment lasts a lifetime. To clean your epoxy resin table, use a soft, damp cloth and a mild soap. Avoid harsh chemicals, abrasive cleaners, or ammonia-based products, as they can dull the finish or cause damage.

Although epoxy is durable, it can be scratched. Always use coasters and placemats to prevent scratches from plates, cups, and other hard objects. Avoid placing hot items directly on the surface.

Keep the table in a stable environment. Drastic temperature and humidity fluctuations can cause the wood to expand or contract, potentially stressing the epoxy. For minor scratches, you can often buff them out with a fine-grit polish. Deeper chips or cracks may require a professional to repair.

Epoxy Tables Cost: Pricing and Value

The price of an epoxy table can vary dramatically. Factors affecting the epoxy furniture cost include the size of the table, the type and rarity of the wood, the complexity of the design, and the quality of the resin.

A small, DIY epoxy coffee table might cost a few hundred dollars in materials. In contrast, a large, custom-made dining table from a reputable artist can cost anywhere from $5,000 to $20,000 or more. While the initial investment for a custom epoxy table price can be high, these tables are durable, functional pieces of art that hold their value well over time.

Where to Buy Epoxy Tables or Materials

If you’re ready to buy, you can find ready-made epoxy tables online on sites like Etsy, or through custom furniture makers. Many local woodworkers also specialize in epoxy furniture.

For DIY enthusiasts, epoxy table suppliers like Rockler Woodworking and Woodcraft offer a wide range of resins and tools. You can also find high-quality epoxy resin online directly from manufacturers. For wood, look for local lumberyards or specialty wood suppliers.

Epoxy Tables vs. Traditional Wood Tables

When comparing an epoxy vs wood table, several factors come into play. Epoxy tables offer unparalleled design freedom and a unique, modern aesthetic. They are also highly durable and resistant to moisture.

However, traditional wood tables have a classic, timeless appeal that some may prefer. Solid wood can also be refinished multiple times over its life. The choice between epoxy resin vs traditional wood often comes down to personal style and preference.

Epoxy Table Design Ideas for Every Space

Epoxy furniture inspiration is everywhere. In a living room, a “river” coffee table can be a stunning focal point. In an office, an epoxy desk can bring a touch of nature and creativity to the workspace. For a dining room, a large epoxy table can create an unforgettable gathering spot.

When choosing a design, consider your existing home decor. A rustic space might benefit from a live-edge table with clear or subtly colored resin, while a modern room could handle a bold, artistic design with vibrant colors.

Also Check: “drink table“

The Future is Custom

Epoxy tables represent a beautiful fusion of natural materials and human creativity. They offer a unique opportunity to own a piece of furniture that is not just functional but also a true work of art. Whether you decide to take on a DIY project or invest in a custom-made piece, an epoxy table is a valuable addition that will bring character and style to your home or office for years to come.

Frequently Asked Questions (FAQ)

How long does it take to make an epoxy table?

The time it takes can vary greatly depending on the complexity and size. A small coffee table might take 40-50 hours of work spread over one to two weeks, accounting for pouring and curing times. A large dining table could take over 100 hours and span several weeks.

Is it safe to use epoxy for furniture?

Once fully cured, high-quality, food-grade epoxy resin is inert and non-toxic, making it safe for surfaces that may come into contact with food. However, it’s crucial to work in a well-ventilated area and use personal protective equipment (gloves, respirator) when mixing and pouring liquid epoxy, as the fumes can be harmful.

Can epoxy tables be used outdoors?

Yes, but with caution. If an epoxy table is to be used outdoors, it must be made with a high-quality, UV-resistant epoxy to prevent yellowing and degradation from sun exposure. It should also be protected from extreme weather conditions.

How do you fix an epoxy table if it gets damaged?

Minor scratches can often be buffed out using a fine-polishing compound. For deeper scratches or chips, you may need to sand the affected area and apply a new topcoat of epoxy. For significant damage, it’s best to consult a professional furniture maker who specializes in epoxy.